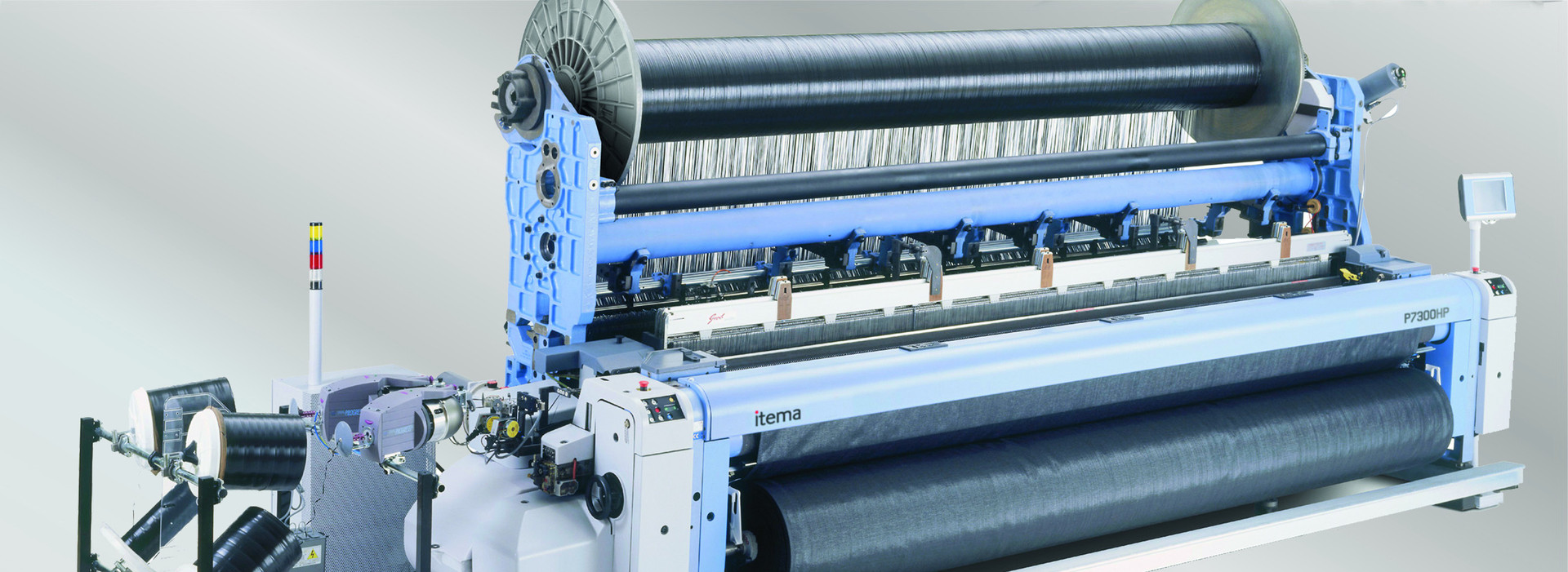

Itema is a family-owned business and the world’s largest manufacturer of textile machinery. More than 300,000 weaving machines made by Itema are currently in use all over the world, producing high-end fashion fabrics, mass-produced goods, and industrial fabrics. Since acquiring Sulz-based Rüti AG, Itema is the only company that – with its rapier, airjet, and projectile looms – offers the three leading weft insertion technologies used in textile weaving, allowing them to offer the perfect weaving machine for each application. Steeped in tradition and with a fast and reliable service, they help to ensure maximum production capability of their systems in over 100 countries. It is their range of projectile looms that is particularly well known for its outstanding spare parts service. Itema stores spare parts for machines up to 30 years old, with 95 percent of the company’s spare parts being in permanent stock.

100,000 spare parts in permanent stock

To maintain such a unique service and to supply their own assembly plants, Itema operates a state-of-the-art logistics center at their Zuchwil site in Switzerland. The centralized parts warehouse comprises an automated small parts warehouse (AKL), a high-bay pallet warehouse, and a manual warehouse for small parts. The conventional warehouse area is connected with the automated small parts warehouse and the high-bay pallet warehouse by means of automated materials handling technology. Approximately 56,000 different items and a total of 100,000 parts are stored in Zuchwil. Orders are consolidated using a sorting system with 40 stations.

To further modernize their warehouse processes, Itema was looking for new logistics software that would replace their own systems which they had partially developed themselves. “Due to the wide range of warehouse technologies used, we needed several different software solutions that would work together efficiently,” Urs Kienast explains, in charge of Itema’s warehouse systems. The company was hoping that the new warehouse management software would help to increase the security of their systems. Furthermore, with their move to MDE picking in their manual and long parts warehouses, the efficiency of their order consolidation processes was to be increased significantly as well. When it came to system implementation, then, they opted for Ehrhardt Partner Group (EPG) due to their many years of experience in warehouse management. As the main contractor, logistics expert EPG delivered their warehouse management system (LFS), a Warehouse Control System (WCS), and a PLC control system. The new systems were implemented during regular operations.

Varying logistical demands

In order to meet the demands both of production and of the spare parts service, LFS offers two different interfaces for the existing ERP system. The warehouse management system separately coordinates item consolidation for production and for the global spare parts orders placed by customers. At their Zuchwil site, Itema supplies their production in a just-in-sequence manner: order consolidation at the warehouse follows the production cycle. Each component is supplied to a very specific production slot in the correct order, in the correct quantity, and at the right time. When it comes to warehouse processes in relation to Itema’s global spare parts service, on the other hand, speed is of the essence. LFS manages order consolidation such that all spare parts within Europe can be delivered within 24 hours. Worldwide, Itema guarantees delivery within 48 hours.

LFS manages warehouse capacity

Alongside LFS implementation, Itema have also changed their picking strategy, with MDE replacing the paper-based picking process in their manual warehouses. Every month, Itema processes up to 20,000 items for their spare parts service alone; another 4,000 items are picked by staff on a monthly basis to supply their own assembly lines. This is in addition to 4,000 putaways each month. “By using MDE we were able to make work significantly easier on our staff,” Daniel Barrer explains, Warehouse Manager at Itema-Group. “Picking speed has increased, and error rates have decreased.” In addition to the picking process, LFS also manages order consolidation along the sorting system with its 40 stations. LFS assigns a sorting lane to each individual order. The more lanes are activated, the more orders are being consolidated in tandem. This warehouse management system allows staff and warehouse capacities to be managed, for example. The manual warehouse area is connected with the small parts warehouse and the pallet warehouse by means of materials handling technology.

Following their modernization of the logistics center, the spare parts service of the entire Itema-Group was relocated to Zuchwil, Switzerland. This project, therefore, has helped Itema to retain Switzerland’s competitive edge as a business location. LFS helps to achieve a processing time of only 3.5 hours. Furthermore, the sorting control system improves order consolidation from the various warehouse areas. Approximately 800,000 picks are carried out in Zuchwil each year – that is up to 5,000 metric tons in goods! “EPG’s efficient process workflows are a reflection of our many years of experience,” Michael Tüfer explains, Branch Manager at EPS, Ehrhardt Partner Solution AG in Switzerland. “We run a highly efficient logistics center with state-of-the-art logistics software, allowing us to continue offering our high-quality service to our customers.” Because this project was so successful, additional modernizations are already in the planning – including switching over to LFS software version 8.